EPOXY & GLASS COUNTERTOP

I needed a new counter top and wanted to use glass since it was no longer being recycled. I decided to turn theses two problems into a project to help solve them both.

The Counter Top Process:

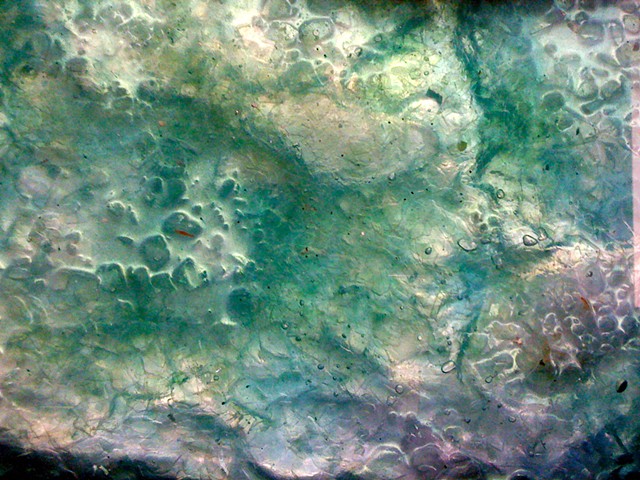

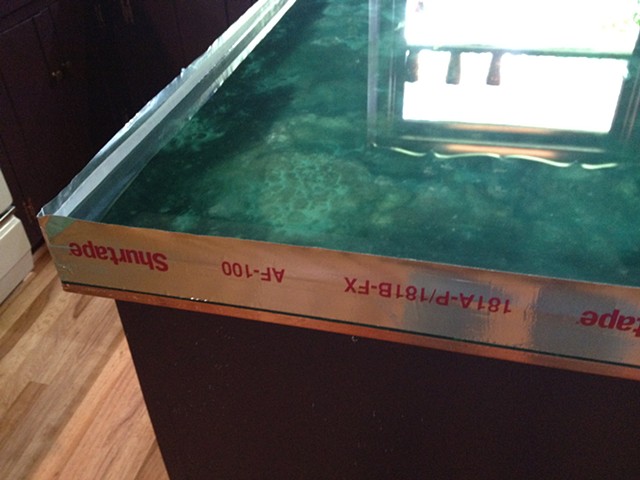

I created plexiglass dam to hold the glass and epoxy. First I sealed the inside of the box with epoxy, then laid mirror in the bottom of the box. Each day I laid in glass that I had tumbled in a cement mixer. Each day I mixed epoxy and poured in 1/8. The epoxy I used was not a casting epoxy so it could not be poured all at once. I also mixed in dry pigments with the resin before adding the hardener to keep the color as consistent as possible. Interference dry pigments were also used to create the sense of looking through water. Once the final coat was poured, and allowed to dry for weeks, the plexiglass sides were pried off and the epoxy edge that crawled up the edge was trimmed and sanded and a small amount of epoxy was wiped on to sanded edge to make it smooth. A copper edge was then applied to the bottom of the piece to for decor.

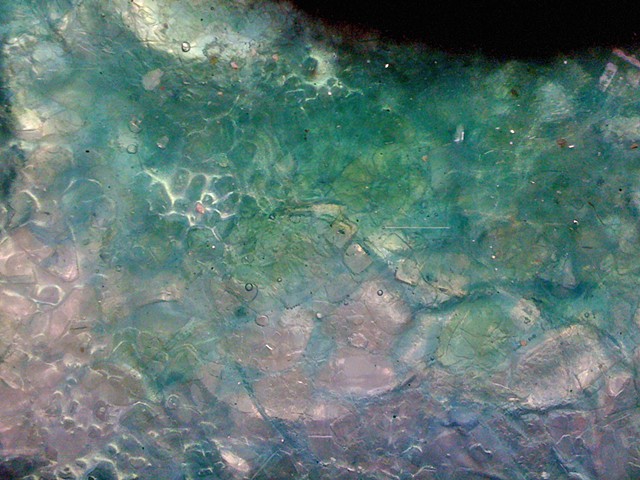

The Island Process

The Island was done in much the same way except I had a plexiglass box made and embedded bubble wrap and discarded blister wrap along with the glass shards. It took 4 people to carry the top into the house. The cabinet was a found object from the street. It was transformed into what you see by friend, Tim who also helped with all the epoxy and cabinet work. He added a back, doors, drawers and inside pull out shelving. I could not have done the whole project without Tim.